Most Popular Products

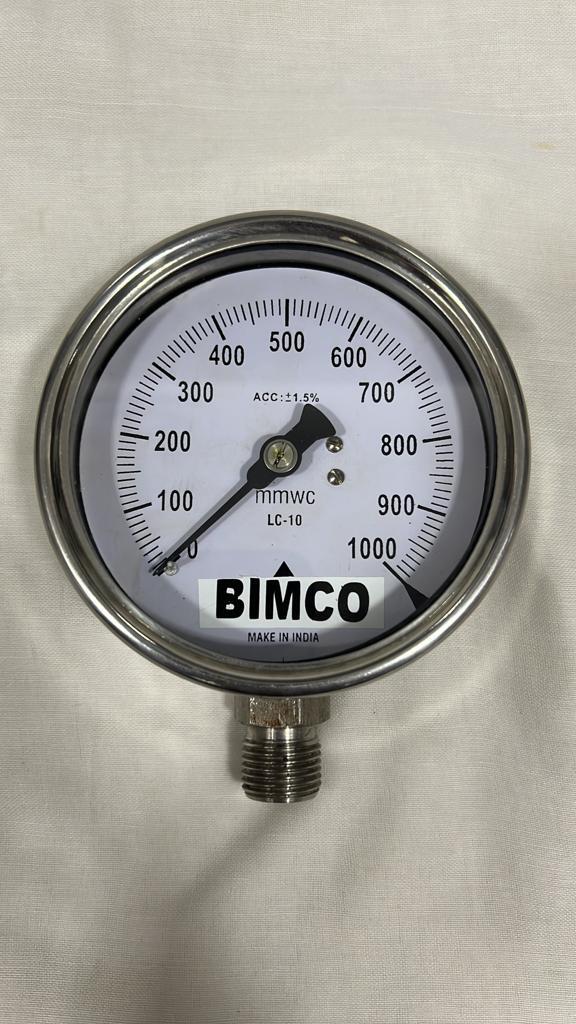

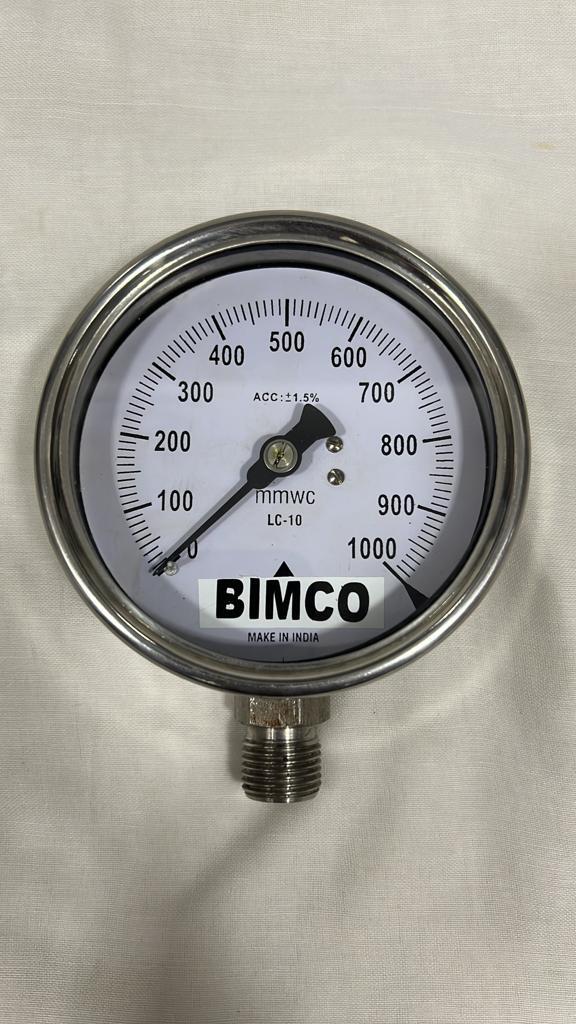

Magnehelic Differential Pressure Gauges

Magnehelic Differential Pressure Gauges Specification

- Thread

- BSP (M), NPT (F)

- Display

- ANALOG

- Usage

- INDUSTRIES / LAB

- Size

- 1/4" to 4"

- Working Presssure

- 15 BAR

- Product Type

- Differential Pressure Gauge

- Color

- GREY

- Accuracy

- +/-1 %

Magnehelic Differential Pressure Gauges Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- MUMBAI

- Payment Terms

- Others

- Supply Ability

- 350 Per Month

- Delivery Time

- 1 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Africa

- Main Domestic Market

- All India

About Magnehelic Differential Pressure Gauges

Experience the rarefied quality and glorious precision of the Magnehelic Differential Pressure Gauges, setting a redoubtable standard for process industries and laboratories in India. With a robust stainless steel casing, these gauges support working pressures up to 15 BAR and deliver exceptional accuracy of +/-1%. Available in sizes from 1/4" to 4" with BSP (M) and NPT (F) threading, their analog display and glycerine-filled dial ensure stable, reliable readings. In demand for industrial monitoring, these cost-effective gauges are available through trusted distributors, exporters, and suppliers in Indiareserve yours today for assured performance.

Advantages and Machine Features of Magnehelic Differential Pressure Gauges

Magnehelic Differential Pressure Gauges offer robust advantages such as precise measurement, low maintenance, and outstanding durability. Relying on a liquid-filled (glycerine) dial, these gauges stabilize readings and minimize vibration effects. Featuring stainless steel wetted parts and glass windows, the instruments are ideally suited for use in both process industries and laboratory environments. Simple vertical mounting and analog display make application and monitoring straightforward, ensuring dependable operation under demanding industrial conditions.

Certifications, Delivery, and Market Value Overview

These Magnehelic Differential Pressure Gauges are supplied with reliable certifications assuring consistent quality. Typically, delivery time aligns with industry standards, offering prompt supply and secure FOB port shipping options to optimize logistics. With a cost-effective outlay, businesses receive substantial market value, minimizing operational costs without sacrificing precision or performance. As a highly sought-after product in both domestic and export markets, these gauges represent both quality and value to process industry professionals.

Advantages and Machine Features of Magnehelic Differential Pressure Gauges

Magnehelic Differential Pressure Gauges offer robust advantages such as precise measurement, low maintenance, and outstanding durability. Relying on a liquid-filled (glycerine) dial, these gauges stabilize readings and minimize vibration effects. Featuring stainless steel wetted parts and glass windows, the instruments are ideally suited for use in both process industries and laboratory environments. Simple vertical mounting and analog display make application and monitoring straightforward, ensuring dependable operation under demanding industrial conditions.

Certifications, Delivery, and Market Value Overview

These Magnehelic Differential Pressure Gauges are supplied with reliable certifications assuring consistent quality. Typically, delivery time aligns with industry standards, offering prompt supply and secure FOB port shipping options to optimize logistics. With a cost-effective outlay, businesses receive substantial market value, minimizing operational costs without sacrificing precision or performance. As a highly sought-after product in both domestic and export markets, these gauges represent both quality and value to process industry professionals.

Product details

|

Minimum Order Quantity |

1 Piece |

|

Country of Origin |

Made in India |

|

Material of Casing |

Stainless Steel |

|

Model Name/Number |

BI-777 |

|

Connection Type |

NPT |

|

Accuracy Class |

1 |

|

Connection Size |

1/8 inch |

|

Dial Size |

2.5 inch / 63 mm |

|

Dial Type |

Liquid Filled |

|

Display Type |

Analog |

|

Liquid Filling |

Glycerine |

|

Mounting |

vertical |

|

Pointer Material |

Aluminium Black |

|

Pressure Range |

As per requirement |

|

Pressure Type |

Differential Pressure |

|

Use |

Process Industries |

|

Wetted Parts |

Stainless Steel |

|

Window Material |

Glass |

FAQs of Magnehelic Differential Pressure Gauges:

Q: How accurate are Magnehelic Differential Pressure Gauges?

A: These gauges offer an accuracy of +/-1%, making them highly reliable for precise measurement needs in industrial and laboratory environments.Q: What are the main applications of these gauges?

A: Magnehelic Differential Pressure Gauges are widely used in process industries and labs for monitoring and controlling differential pressure in various systems, ensuring safety and efficiency.Q: What is the process for installing the gauge?

A: Installation involves vertical mounting, connecting to the system using compatible BSP or NPT threaded fittings, and ensuring the analog display is easily readable.Q: When will my order be delivered?

A: Delivery times typically adhere to standard industry timelines, with shipping options available through secure FOB ports as per customer requirements.Q: Where are these gauges made and what about their certifications?

A: Manufactured in India, the Magnehelic Differential Pressure Gauges come with relevant certifications to guarantee quality and reliability in professional applications.Q: What is the minimum order quantity?

A: The minimum order quantity for Magnehelic Differential Pressure Gauges is one piece, allowing even small operations to benefit from their precision.Q: How cost-effective are these gauges for industrial use?

A: Offering strong durability and minimal maintenance, these gauges provide a market value that lowers overall outlay, making them a cost-effective solution for industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

BOMBAY INSTRUMENTS MFG. CO./ AADESHWAR OVERSEAS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |